Pressure Loss in an RPZ Backflow

I will be installing a 6-inch Reduced Pressure Principle Assembly on an existing system. Can you tell me what the “pressure loss” or CV factor is for that particular assembly?

Mark

This is a very common question that is asked by plumbing contractors, fire line contractors, and even engineers for new or retrofit backflow assembly installations. Anytime a backflow assembly is specified for an installation, it is very important to know what the pressure loss is for the assembly. The problem we find many times is that the answer can be easily misunderstood. For example, when we call our suppliers and ask this question, normally they will look it up and find a flow curve and not a specific number. This can be confusing, so many times they may guess, or give an estimate of the overall pressure loss. It is important that we understand how it is represented on a flow curve, so that loss can be calculated correctly.

Doug

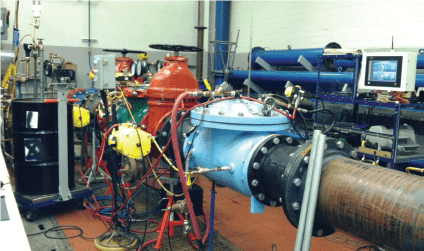

Basically, pressure loss is present in any plumbing system. It normally starts with the friction of the water against the interior walls of “fixed orifice items” such as pipes, valves, and fittings. They are called fixed orifice items simply because the pathway that the water flows through does not change. The loss for a fixed orifice item is identified as the CV factor. A backflow prevention assembly is not a fixed orifice item so it cannot have a CV factor. The check valves within the assembly are force loaded to the closed position. This means that the orifice or pathway that the water flows through is constantly changing (As the flow of water increases or decreases, the check valves are opening and closing). This opening and closing of the check valves change the amount of friction within the assembly.

Mark

With that in mind, the best way to show the flow characteristics of a backflow preventer is by a “pressure loss verses flow rate” curve. This type of flow curve will show the pressure loss of the assembly throughout its full range of operation not just at a single point. So, to determine the loss, we need to know at what flow rate the assembly will be operating. Then it is just a matter of reading the curve. We know that as the flow rate varies, the loss through the assembly will vary as well. For example, you could have a 6-inch reduced pressure principle assembly that has a pressure loss of 12 PSI at 140 GPM and then a pressure loss of 9.5 PSI at 840 GPM.

Doug

It is also important to remember that the values we get from a flow curve are for the assembly itself and does not include any of the piping and fittings required to install the assembly. From time to time we get questions concerning pressure loss tables that are published by approval agencies. These tables are used to show the ”maximum allowable pressure loss” requirement for a specific size and type of backflow prevention assembly.

Basically, these tables show the standard by which assemblies are evaluated by that agency or laboratory. To find the pressure loss for a particular model of backflow preventer, you will normally have to refer to the manufacturer’s specification sheet.